The Best Overview to Sublimation Printing for Custom-made Clothing

The Best Overview to Sublimation Printing for Custom-made Clothing

Blog Article

A Comprehensive Guide to the Different Kinds of Fabric Printing Strategies

Each technique, from the meticulous craftsmanship of block printing to the fast effectiveness of screen printing, offers unique objectives and supplies distinct benefits. Digital printing's adaptability and ecological consciousness stand in stark contrast to the swift personalization of warm transfer printing.

Block Printing

Block Printing, one of the oldest approaches of fabric design, has a rich history that dates back to old civilizations. The procedure entails carving elaborate layouts right into wood blocks, which are then dipped in dye and pressed onto textile to create patterns.

The accuracy and craftsmanship involved in block printing make it a labor-intensive procedure, however it also enables a high level of customization. Craftsmens can produce unique patterns by incorporating different blocks or differing the application of dye. This flexibility has actually added to the long-lasting popularity of block printing in both traditional and modern textile layout.

Block printing is especially valued for its visual top qualities, including the slight variations in pattern and shade that result from the hand-printing process. These flaws lend an one-of-a-kind personality to every item, identifying it from mass-produced textiles. Despite advancements in modern printing innovations, block printing continues to be a treasured method, commemorated for its historic relevance and artistic worth.

Display Printing

Display printing, another famous fabric design strategy, has changed the industry with its effectiveness and convenience. This method involves producing a pattern, called a screen, and using it to use layers of ink on the printing surface area. Each shade in the design needs a different display, which permits for intricate and lively multi-colored prints.

One of the crucial benefits of display printing is its flexibility to numerous sorts of fabrics, including cotton, polyester, and blends. This technique is particularly appropriate for large-volume orders because of its cost-effectiveness and speed. The longevity of the prints is another significant advantage, as the ink bonds well with the fabric, making sure resilient styles that stand up to numerous cleans.

When dried, the style is transferred onto the emulsion-coated display making use of a UV light resource. Ink is after that pressed with the pattern onto the textile making use of a squeegee.

Display printing is widely made use of in the apparel industry, marketing products, and custom-made apparel. Its capacity for top quality, in-depth prints safeguards its condition as a foundation technique in textile printing.

Digital Printing

Digital printing has actually quickly become a sophisticated strategy in the textile industry, leveraging advanced modern technology to produce high-resolution layouts directly onto fabric. Unlike traditional techniques, digital printing employs inkjet printers to down payment pigment or dye-based inks onto fabrics, allowing vivid and complex patterns with a remarkable level of detail and shade precision.

One of the key advantages of electronic printing is its flexibility. This approach enables on-demand printing, which dramatically decreases waste and decreases stock prices. Additionally, it supports brief runs and customized layouts, making it excellent for limited-edition collections and custom projects. The removal of displays and other arrangement requirements even more boosts performance, reducing manufacturing time and labor expenses.

Moreover, electronic printing is eco-friendly. DTF printing. It utilizes water-based inks and needs much less water and power contrasted to conventional methods, straightening with lasting techniques. The accuracy of digital printing also allows making use of a larger series of fabrics, consisting of cotton, silk, polyester, and blends, guaranteeing adaptability throughout various applications

Warm Transfer Printing

Just how does warmth transfer printing reinvent textile layout? Warmth transfer printing entails making use of warmth and pressure to transfer a design from a particularly developed paper onto fabric.

Among the main advantages of heat transfer printing is its capacity to create high-quality, detailed photos swiftly and effectively. It is especially well-suited for tiny production runs and customized orders, making it a popular selection for individualized apparel and marketing things. Furthermore, this technique is flexible, suiting different kinds of fabrics consisting of cotton, polyester, and blends.

Furthermore, warmth transfer printing is fairly cost-effective compared to various other article methods, as it needs marginal setup and reduced first investment - Branded clothing. This cost, paired with its capacity for generating lively, resilient prints, emphasizes its pivotal function in modern-day fabric style

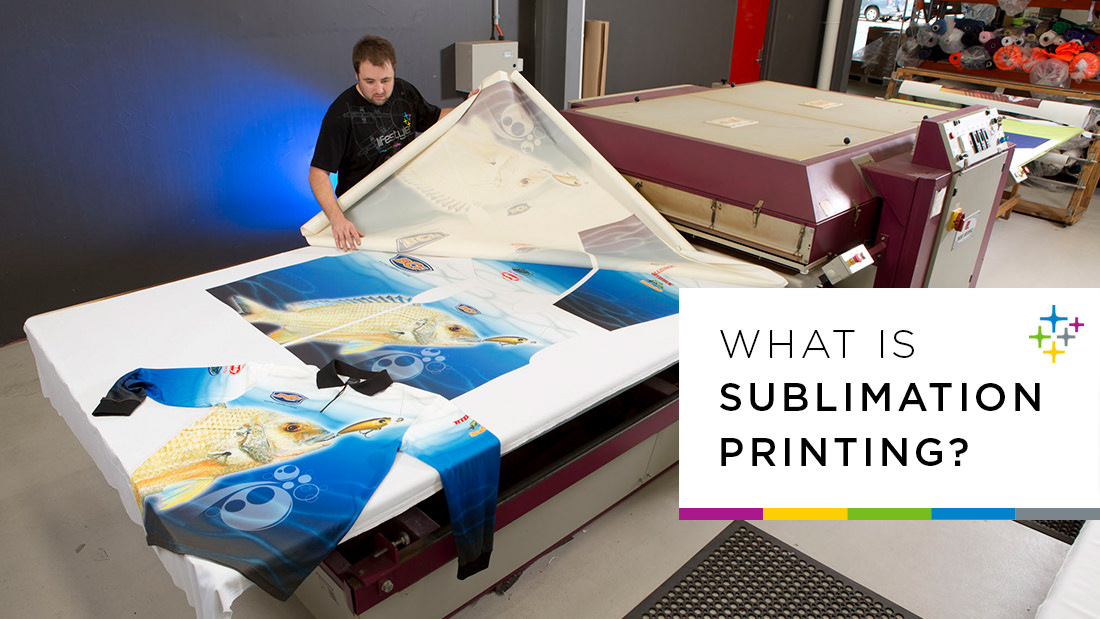

Dye Sublimation Printing

Dye sublimation printing, an advanced fabric printing technique, supplies unparalleled vibrancy and long life for styles on different synthetic textiles. The published transfer paper is then positioned on the textile, and both are subjected to high heat and stress using a warmth press.

One of the essential advantages of color sublimation printing is its ability to generate continuous-tone prints with complex details and vibrant shades. Unlike other printing techniques, the dye enters into the textile this link instead of resting on top of it, leading to a soft and breathable coating. This technique is specifically effective on polyester and various other synthetic products, making it a popular selection for sportswear, banners, and home fabrics. Furthermore, color sublimation is eco-friendly, as it requires no water and creates minimal waste, lining up with sustainable production techniques.

Verdict

In summary, fabric printing techniques each deal unique benefits customized to numerous needs and applications. Block printing is admired for its artisanal top quality, while display printing is advantageous for high-volume production. Digital printing gives flexibility and you can check here ecological benefits, whereas warmth transfer printing is excellent for rapid customization. Dye sublimation printing generates brilliant, long lasting designs on artificial materials. The variety and development within these approaches highlight the dynamic and progressing nature of the fabric printing sector.

Each technique, from the careful workmanship of block printing to the quick efficiency of screen printing, serves distinct functions and supplies distinct benefits. Digital printing's adaptability and environmental consciousness stand in plain comparison to the quick personalization of warmth transfer printing. Despite advances in modern printing innovations, block printing remains a cherished technique, celebrated for its historic significance and artistic worth.

Dye sublimation printing, an innovative material printing method, provides unparalleled vibrancy and longevity for layouts on numerous artificial textiles. Digital printing gives versatility and environmental benefits, whereas warmth transfer printing is optimal for rapid customization.

Report this page